Unlock Every Stage of Product Development with EM Simulation

The journey from a groundbreaking idea to a certified, market-ready product is complex and fraught with risks. On this day and age, Electromagnetic (EM) Simulation is no longer a luxury—it’s the critical, cost-saving engine that drives success at every stage of the product development lifecycle.

From the lab bench to the factory floor, here’s how EM simulation helps engineers and product teams de-risk, optimize, and outperform the competition.

🔬 Stage 1: Proof of Concept & Feasibility

The earliest stage of innovation is often the riskiest. Before you commit time and budget to physical prototypes, you need to know your idea will actually work. EM simulation provides a virtual R&D lab to validate the foundational science of your product.

- Validate Groundbreaking Ideas: You can instantly prove novel EM concepts and test non-standard geometries without waiting weeks for a part to be milled.

- De-Risk R&D: Virtually test high-risk ideas, eliminating potential showstoppers early (often within Technology Readiness Levels TRL 1-3). This is where you find out if a critical component or material will cause an insurmountable problem before you invest heavily.

- Strengthen IP Development: Detailed simulation data and validated concepts provide compelling technical evidence to strengthen patent applications and bolster your Intellectual Property (IP).

🏁 Stage 2: Benchmarking & Analysis

A great product isn’t just functional; it’s competitive. Understanding the competitive landscape is crucial for strategic product decisions and marketing positioning.

- Model the Competition: You can virtually model and benchmark competitor product performance, accurately identifying their design strengths, weaknesses, and key trade-offs.

- Quantify Your Advantage: Simulation provides the quantitative data needed to directly compare your design’s advantages side-by-side. This data can inform critical strategic decisions to ensure your product not only meets but outperforms the competition in the market.

- Achieve Competitive Edge: By understanding the performance limits and compromises of existing products, your team can pivot to target an unserved need or exploit a known weakness.

🎯 Stage 3: Design Optimization and Tuning

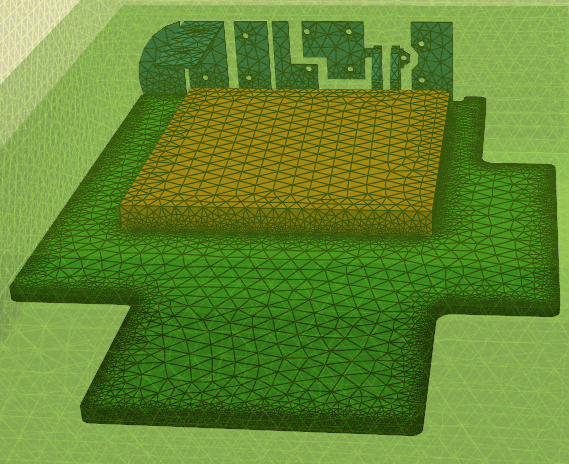

Once the core concept is proven, the focus shifts to refinement. This is the stage where performance, size, and cost are balanced. EM simulation transforms this iterative, often frustrating, process into a data-driven science.

- Optimize for Peak Performance: Refine CAD models to achieve optimal key metrics—whether it’s maximizing gain for an antenna, achieving perfect impedance matching on a PCB, or ensuring low SAR (Specific Absorption Rate) for a wearable device.

- Automate Trade-Off Analysis: Simulation tools allow engineers to automate parameter sweeps, quickly exploring hundreds of design variations to find the perfect trade-off between performance, manufacturability, and cost.

- System Integration Analysis: Beyond the component itself, you can analyze how the design performs within the real world. This includes assessing the effects of enclosures, adjacent components, and even the human body on the EM performance, drastically reducing the number of costly physical prototype iterations.

🛡️ Stage 4: EMC/EMI & Standards Compliance

The final hurdle before shipping is certification. Failing an EMC (Electromagnetic Compatibility) or EMI (Interference) test is one of the most common and expensive delays in product development, often forcing a late-stage, costly redesign.

- De-Risk Certification: Simulation allows you to predict radiated and conducted emissions (required for standards like FCC, CE, and CISPR) and assess immunity to external electromagnetic disturbances before stepping into a costly anechoic chamber.

- Virtual Mitigation Testing: Teams can virtually test and validate mitigation strategies—such as adjusting shielding, optimizing filtering circuits, or refining grounding—all on the computer, long before final hardware is fabricated.

- Prepare for Global Standards: Simulation is essential for preparing your product for rigorous industry and safety standards, including IEC 60601 (Medical), MIL-STD-461 (Military), RTCA DO-160 (Aerospace), and ISO 11451/2 (Automotive). Ensuring compliance early is the key to a fast, stress-free path to market.

The Simulation Advantage

EM Simulation transforms product development from a costly, linear process of build-and-test into a parallel, data-rich environment. By integrating virtual prototyping at every stage, your team can cut costs, accelerate time-to-market, and launch a superior, certified product.

Ready to move beyond guesswork and bring the power of virtual engineering to your product pipeline?

Ready to Start Your Project?

Let's discuss your electromagnetic engineering needs and find the right approach for your project.